Our addiction to our cell phones, laptops, the growth of electric vehicles and other personal electronic devices drives an increased market need for more batteries.

As our use cases for batteries grow, so too does our need for recycling these critical and rare elements.

There’s a great quote about battery recycling: “The largest lithium and cobalt reserves in the western hemisphere [are] locked away in America’s junk drawers”.

Our iPhone and other consumer electronic batteries have used LCO as the cathode material since commercialization in the 1980s. How could we make sure that these iPhone batteries are contributing to a circular American supply chain? What if once cobalt made it to the US, it never left?

There are a few companies working on battery recycling to reduce the environmental impact of manufacturing batteries, while also lowering demand for rare materials.

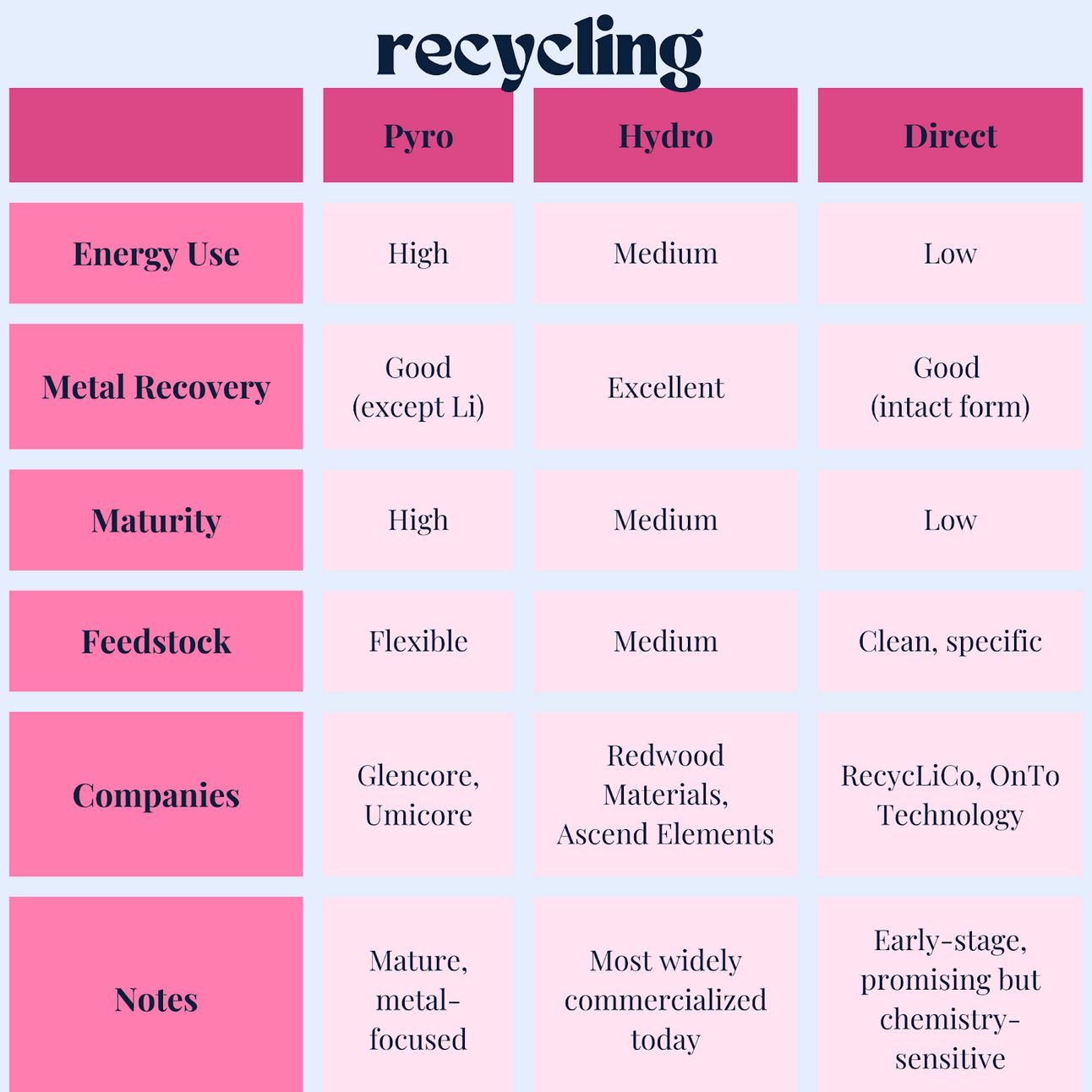

There are three main types of battery recycling: pyrometallurgical, hydrometallurgical, and direct recycling.

Pyrometallurgical Recycling

What it is:

High-temperature processing (smelting) to extract valuable metals

How it works:

Batteries are shredded or incinerated

Organic materials and plastics burn off

Metals melt and separate based on density

What you get:

Recover metals like cobalt, nickel, and copper as alloys or oxides

Lithium and aluminum are often lost or go to slag (smelting byproduct)

Pros:

Mature and industrially scalable

Handles mixed chemistries easily

Cons:

Energy-intensive (high heat)

Poor lithium recovery

Destroys cathode structure, so no reuse of active materials

Hydrometallurgical Recycling

What it is:

Uses acid or base solutions to dissolve and recover metals

How it works:

Batteries are disassembled/shredded

Leaching agents dissolve the metals

Metals are selectively precipitated or extracted

What you get:

High purity recovery of cobalt, nickel, lithium, manganese

Pros:

Lower energy use than pyro

Good lithium recovery

Scalable and adaptable to different chemistries

Cons:

Generates chemical waste

Still destroys cathode structure

More complex separation process

Direct Recycling

What it is:

Tries to preserve and rejuvenate the cathode material directly

How it works:

Batteries are carefully disassembled

Cathode powder is harvested

Physical and chemical methods restore structure and composition

What you get:

Reconditioned cathode ready for reuse

Pros:

Lowest energy use

Maintains material structure, ideal for reuse

Potentially cheapest and most sustainable long term

Cons:

Not yet mature at scale

Chemistry-specific, harder with mixed-streams

Requires clean, well-sorted feedstock

Conventional battery recycling methods—such as pyrometallurgy and hydrometallurgy—break down batteries to recover individual metals. These metals are then reprocessed into battery-grade precursors, effectively serving as a form of "urban mining." In contrast, direct recycling aims to recover and restore battery components—particularly the cathode—while maintaining their original crystal structures. This approach avoids the energy- and cost-intensive steps of breaking down and re-synthesizing materials. [1]

Pyrometallurgical and hydrometallurgical methods for recycling spent lithium-ion batteries are moving toward commercial use.

Companies using pyro: Li-Cycle (initially), Umicore, Glencore.

Companies using hydro: Li-Cycle, Redwood Materials, Ascend Elements

Companies direct recycling: RecycLiCo (American Manganese), Battery Resourcers (merged with Ascend), OnTo Technology, Princeton NuEnergy

According to the EverBatt model, direct recycling offers significant economic and environmental advantages. Producing 1 kg of NMC111 cathode via direct recycling results in a 44% cost reduction compared to using virgin materials. It also cuts energy consumption by 14% compared to hydrometallurgical recycling and 25% compared to pyrometallurgical methods.[2]

Lab-scale demonstrations of direct recycling have shown promising results across various chemistries, including LFP[3], LCO[4], NMC[5,6–9], and graphite[10]. However, one of the major hurdles to commercialization is the manual separation of battery components, which is labor-intensive and inefficient at scale [1,2].

Unlike pyrometallurgical and hydrometallurgical processes—which typically grind and mix battery cells into a composite “black mass”—direct recycling requires careful disassembly. Individual cell components, such as the cathode and anode, must be separated cleanly. For example, recovering cathode material often involves detaching active mass from the aluminum current collector, commonly using solvents like NMP to dissolve the PVDF binder.

A shift toward a standardized cell design could significantly enhance the commercial viability of direct recycling, enabling automation and reducing processing complexity. [2,7-10]

Some Resources We Love :

This paper on NMR analysis of recycled battery materials has great background on NMC recycling and also covers upcycling to higher Ni content NMC.

Sources

1. Toro, L. et al. A Systematic Review of Battery Recycling Technologies: Advances, Challenges, and Future Prospects. Energies 16, 6571 (2023).

2. Ma, X. et al. The evolution of lithium-ion battery recycling. Nat. Rev. Clean Technol. 1, 75–94 (2025).

3. Xu, P. et al. Efficient Direct Recycling of Lithium-Ion Battery Cathodes by Targeted Healing. Joule 4, 2609–2626 (2020).

4. Sloop, S. et al. A direct recycling case study from a lithium-ion battery recall. Sustain. Mater. Technol. 25, e00152 (2020).

5. Gupta, V. et al. Scalable Direct Recycling of Cathode Black Mass from Spent Lithium-Ion Batteries. Adv. Energy Mater. 13, 2203093 (2023).

6. Montoya, A. T. et al. Direct Recycling of Lithium-Ion Battery Cathodes: A Multi-Stage Annealing Process to Recover the Pristine Structure and Performance. ACS Sustain. Chem. Eng. 10, 13319–13324(2022).

7. Shi, Y., Zhang, M., Meng, Y. S. & Chen, Z. Ambient-Pressure Relithiation of Degraded LiNi0.5Co0.2Mn0.3O2 (0 < x < 1) via Eutectic Solutions for Direct Regeneration of Lithium-Ion Battery Cathodes. Adv. Energy Mater. 9, 1900454 (2019).

8. Shi, Y., Chen, G., Liu, F., Yue, X. & Chen, Z. Resolving the Compositional and Structural Defects of Degraded LiNixCoyMnzO2 Particles to Directly Regenerate High-Performance Lithium-Ion Battery Cathodes. ACS Energy Lett. 3, 1683–1692 (2018).

9. Gao, H. et al. Upcycling of Spent LiNi0.33Co0.33Mn0.33O2 to Single-Crystal Ni-Rich Cathodes Using Lean Precursors. ACS Energy Lett. 8, 4136–4144 (2023).

10. Markey, B. et al. Effective Upcycling of Graphite Anode: Healing and Doping Enabled Direct Regeneration. J. Electrochem. Soc. 167, 160511 (2020).